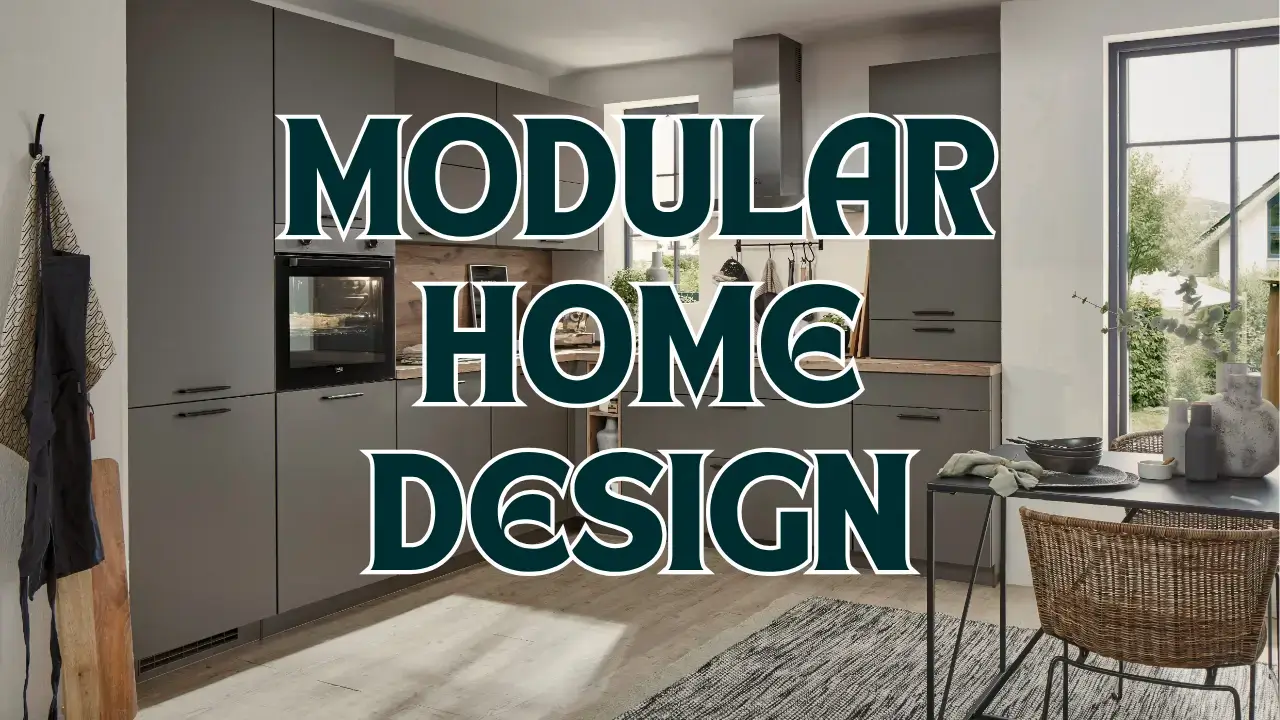

Introduction

Are you dreaming of building your own home but worried about skyrocketing costs and unpredictable timelines? Enter the modular home design cost estimator—your go-to solution for planning and budgeting a modern, cost-effective, and customizable home. As more homeowners seek affordable and sustainable housing alternatives, modular homes have become an increasingly popular choice. These factory-built homes offer high quality, faster construction, and substantial savings compared to traditional stick-built houses.

A modular home design cost estimator helps you understand the financial aspects of building a modular home, from the base price per square foot to site preparation, delivery, permits, and more. Whether you’re considering a compact starter home, a spacious family residence, or a luxury smart modular home, this tool provides a realistic cost projection tailored to your specific needs and location.

In today’s housing market, where every dollar counts, using a cost estimator is essential for anyone planning a modular home build. It allows you to experiment with different design options, material upgrades, and layout configurations—without any financial guesswork. Plus, it saves you from unexpected budget blowouts by offering a clear, detailed breakdown of expenses before construction even begins.

With the rise of digital tools and smart home technologies, building a home has never been more transparent or efficient. So, if you’re ready to take control of your homebuilding journey, start with a modular home design cost estimator—it’s the smartest first step toward your future home.

What Are Modular Homes?

Modular homes are a modern solution to traditional home building. Unlike traditional homes that are built entirely on-site, modular homes are constructed in sections, or “modules,” in a factory setting. These modules are then transported to the building site and assembled like a giant puzzle. The result? A high-quality, often more affordable home that looks just like a site-built one. Modular homes are built according to the same local and state building codes, offering the same safety and durability, but often with greater efficiency and less waste.

Think of modular construction as the IKEA of homebuilding—but with way more stability and permanence. These homes can range from tiny, 500-square-foot starter homes to luxurious multi-story residences. You might be surprised at the variety and sophistication available today. From sleek, modern designs to cozy, traditional layouts, modular homes are as customizable as your imagination—and budget—allow.

Why Modular Homes Are Gaining Popularity

In recent years, modular homes have surged in popularity for good reason. Housing shortages, skyrocketing real estate prices, and a growing interest in sustainable living have all contributed to this boom. Homebuyers are realizing they can get more bang for their buck with modular homes—better materials, faster construction, and often less environmental impact.

Another big factor? Speed. Traditional home construction can take six months to a year or more. A modular home, by contrast, can often be completed in just a few months. That’s music to the ears of anyone who’s tired of dealing with construction delays, unexpected weather impacts, or contractor shortages. Add in the fact that modular homes are often more energy-efficient, and it’s clear why so many people are turning to this smart, flexible housing solution.

Modular Home Design Cost Estimator

Calculate your modular home cost step by step with individual cost breakdown. Optimize your budget with AI design tools like Coohom, Planner 5D, and Homestyler.

Factors That Influence Modular Home Design Costs

Size and Layout of the Home

Size matters—and not just for space, but for your wallet too. One of the biggest factors in modular home pricing is the size of the home. Naturally, the more square footage you want, the higher the price will be. But it's not just about how big the home is. The layout also plays a role. For example, a single-story open floor plan may cost less per square foot than a multi-story home with a complex layout and multiple rooflines.

Bedrooms and bathrooms also affect the cost. A basic two-bedroom, one-bath modular home will be significantly cheaper than a four-bedroom, three-bath luxury model. Add-ons like porches, garages, and extra rooms for offices or entertainment also add to the final tab. The rule of thumb? The simpler the layout, the lower the cost.

Customization and Design Features

Here’s where the price can really start to climb. Modular homes are like blank canvases, but every splash of creativity adds to the price. Want hardwood floors instead of carpet? Granite countertops instead of laminate? How about custom cabinetry, skylights, or a wraparound porch? These choices all impact the overall budget.

Upgraded appliances, smart home tech, premium windows, and high-end finishes make your modular home unique—but they also add to your cost per square foot. If you're trying to stay within a strict budget, it's smart to identify your must-haves and separate them from the nice-to-haves.

Location and Delivery Charges

Distance can be a deal-breaker when it comes to cost. While your modular home might be built in a factory hundreds of miles away, it still needs to get to your land. Transporting large modular sections isn’t cheap. Costs vary depending on the distance, road access, permits required for wide-load travel, and even local escort vehicle requirements.

And once it’s on your site, you’ll need a crane to set the modules in place—a process that adds another chunk of change. Some remote or difficult-to-access areas might require more specialized equipment, adding thousands more to the project. Be sure to include these logistical expenses in your estimator calculations to avoid unpleasant surprises.

Breakdown of Costs in Modular Home Construction

Base Price per Square Foot

Let’s talk numbers. The base price per square foot for a modular home typically ranges from $50 to $150. This price includes standard construction, basic fixtures, and delivery to your location. It does not include foundation work, site prep, utility hookups, or customization—those come later.

To put it into perspective, a 2,000-square-foot modular home could cost you anywhere from $100,000 to $300,000 for the structure alone. Add more square footage or high-end finishes, and you’ll be inching toward the upper end of that scale quickly. The key here is to use a modular home design cost estimator to help break down and visualize each of these components clearly.

Site Preparation and Foundation Costs

Before your modular home can be set in place, the ground needs to be ready—and that comes at a cost. Site preparation includes clearing the land, grading, and digging for the foundation. Depending on your land’s condition and slope, this could cost between $5,000 and $30,000.

Next up is the foundation. You can choose from a slab, crawl space, or full basement—each with its own cost. A slab foundation is generally the cheapest option, while a full basement adds significant cost but provides extra space. Budgeting $10,000 to $40,000 for this phase is a safe estimate for most areas.

Permits, Taxes, and Legal Fees

Don’t forget the paperwork. You’ll need local building permits, zoning approvals, and inspections throughout the building process. These can cost anywhere from a few hundred to several thousand dollars, depending on where you live. On top of that, some municipalities impose modular-specific fees or impact fees for infrastructure services.

There are also closing costs, property taxes, and insurance premiums to consider. These might not be part of the building process itself, but they are essential financial considerations in your overall cost estimate. Being meticulous here can save you from nasty budget overruns down the line.

Using a Modular Home Cost Estimator Tool

How Does a Cost Estimator Work?

A modular home cost estimator functions like your digital financial compass—it guides you through the maze of expenses associated with building your dream modular home. At its core, this tool uses algorithms to calculate a fairly accurate cost based on the data you input. The magic lies in how it blends square footage, design preferences, customization options, and regional cost data to give you a ballpark figure of what you can expect to spend.

Most estimators are interactive and user-friendly. You plug in your preferences—like number of bedrooms, bathrooms, type of foundation, roofing materials, insulation levels, and more. Then the tool runs its calculations and spits out an estimated cost, often broken down into categories like base construction, transportation, site work, and extras. The more specific you are, the more accurate your estimate will be. It's like having a mini-consultation with a contractor—without the sales pitch.

Key Inputs Required for Accurate Estimation

To get the most precise results from a modular home cost estimator, you'll need to provide a solid amount of detail. Here are the key inputs most tools require:

- Home size (total square footage)

- Number of floors

- Type of foundation (slab, crawl space, or basement)

- Roofing style (flat, gabled, etc.)

- Level of interior finish (basic, mid-range, luxury)

- Material preferences (flooring, countertops, cabinets)

- Location of the build (affects transport and labor costs)

- Delivery distance from the factory

- Utility hookups required (electrical, water, septic, gas)

If you're not sure about some of these details, estimators often provide default values based on regional averages. Still, the more info you can feed the tool, the more valuable the output will be.

Understanding the Output: What It Tells You

Once you've entered all your info, the estimator will generate a report detailing the estimated cost of your modular home. This usually includes a base construction cost, site preparation and foundation cost, delivery fees, and sometimes even a contingency buffer for unexpected expenses.

It might also compare costs for different designs or materials, so you can adjust your choices and instantly see how your budget shifts. Some advanced tools even let you download a PDF report or email the estimate to your builder. Just remember—these tools give you a strong starting point, but not a final price. Always follow up with a licensed modular home builder to validate your results and account for local nuances.

Regional Cost Variations

Cost Differences by State or Region

Not all zip codes are created equal when it comes to modular home costs. Prices can vary dramatically depending on where you're building. For instance, modular home construction in the Northeast or on the West Coast typically costs more due to higher labor rates, land values, and permit fees. In contrast, Southern and Midwestern states often have lower costs for both materials and labor.

To illustrate, a basic 2,000-square-foot modular home might cost around $150,000 in a rural part of Alabama but push $250,000 or more in California or New York. The cost of living in the area, availability of construction crews, and regional building codes all play a part in this pricing rollercoaster.

That’s why using a modular home cost estimator with geo-targeted data is crucial. It ensures your estimate is not only realistic but also tailored to the actual market conditions of your specific area.

Rural vs Urban Area Impact on Cost

Building in a rural area has its perks—like cheaper land and fewer regulatory hurdles—but it also has drawbacks that can affect your final bill. For instance, while land may be less expensive, access to utilities like water, sewage, electricity, and internet might be limited, requiring costly extensions or installations.

On the flip side, urban areas come with their own cost challenges. Land is pricey, permits are often more complicated to secure, and you may have to navigate stricter building codes or historical district rules. And don’t forget about logistical complications—delivering large modular sections into a congested city space can be a nightmare and add significant cost.

It’s a classic trade-off scenario. While rural areas may save you money on land, urban settings might reduce utility costs and offer better infrastructure. Make sure your estimator considers these regional details to give you the most accurate forecast.

Comparing Modular vs Traditional Homes Cost

Price Comparison Overview

Let’s cut to the chase—yes, modular homes are generally cheaper than traditional site-built homes. But how much cheaper? The average cost of a modular home ranges between $50 to $150 per square foot, while traditional homes can easily cost $150 to $250 or more per square foot, especially in high-demand markets.

This difference is largely due to the efficiencies of factory production. Modular home builders purchase materials in bulk, reduce labor waste, and avoid costly delays from weather or on-site mishaps. Plus, controlled environments lead to fewer defects and more consistent quality.

To put it in dollars: building a 2,000-square-foot modular home might cost you around $160,000 to $220,000, while a comparable traditional home could hit $300,000 or more, depending on your location and design choices.

Long-Term Cost Savings of Modular Homes

Modular homes don’t just save you money upfront—they can also lower your costs long-term. For starters, they are often more energy-efficient than traditional homes. Many come with enhanced insulation, energy-efficient windows, and tight construction seals that reduce heating and cooling bills.

Maintenance is another plus. Since modular homes are built under strict quality control, they tend to experience fewer structural issues over time. The use of durable materials and precision engineering means fewer repairs and longer-lasting systems.

There’s also value in speed. The faster construction timeline means less time paying for temporary housing or interest-only construction loans. You’re not just saving money—you’re saving time and stress. Over 10 to 15 years, these savings can add up significantly, giving you more room in your budget for upgrades, vacations, or even early mortgage payoff.

Financing a Modular Home

Mortgage Options Available

Financing a modular home isn’t that different from financing a traditional house—but there are some nuances to be aware of. Many major lenders offer standard mortgage options, including:

- Conventional loans

- FHA loans

- VA loans (for veterans)

- USDA loans (for rural properties)

The key requirement is that the home must be permanently affixed to a foundation and classified as “real property.” If it meets these conditions, it can be financed like any other house. However, if the home is not yet built or delivered, you may need a construction-to-permanent loan, which covers both the building phase and the long-term mortgage.

Loan Considerations for Modular Construction

Lenders may have different guidelines for modular homes, especially during the construction phase. You might be asked for:

- A full cost estimate from your builder

- Blueprints and design plans

- A timeline for delivery and installation

- Proof of land ownership or purchase agreement

Some lenders may also conduct extra inspections or appraisals to verify the quality and value of the home. It’s a smart move to work with a lender experienced in modular construction loans—they’ll know the ropes and help you avoid unnecessary red tape.

Also, keep in mind that while modular homes are generally more affordable, lenders still look at your credit score, debt-to-income ratio, and income stability. Getting pre-approved before starting your project can streamline the process and help you budget with confidence.

Cost-Saving Tips When Designing a Modular Home

Choosing Standard Floor Plans

Custom floor plans are great for making a home feel uniquely yours—but they’re not always great for your wallet. One of the easiest ways to cut costs is to stick with a standard floor plan. Modular builders often have pre-designed layouts that are optimized for efficient construction and material use. These plans require fewer engineering tweaks and are often pre-approved for local codes.

Another advantage of standard plans is speed. Since the factory has likely built this design many times, the construction process is faster and smoother. Less back-and-forth, fewer surprises, and lower engineering fees.

You can still add personal touches—like choosing your finishes, siding, and fixtures—without redesigning the entire blueprint. It’s a balance of individuality and practicality.

Selecting Energy-Efficient Features

Investing in energy efficiency might seem costly upfront, but it’s one of the smartest ways to save money in the long run. Think of it like upgrading to a fuel-efficient car—it pays off every month.

Start with insulation. Opt for higher R-values in walls, floors, and ceilings. Choose double or triple-pane windows, energy-efficient doors, and high-SEER HVAC systems. Solar panels, smart thermostats, and tankless water heaters can also slash utility bills.

Some modular builders even offer energy-efficiency packages or partner with ENERGY STAR programs. Yes, the upfront cost may increase slightly, but you’ll see the return within a few years through reduced monthly expenses—and added resale value.

Case Studies of Real Modular Home Costs

Small-Sized Modular Home

Let’s start small. A compact modular home—say, around 600 to 800 square feet—is ideal for singles, couples, or retirees looking to downsize. These homes typically include one bedroom, one bathroom, a kitchen, and a living space, all cleverly packed into a highly efficient layout. Depending on your customization level, the total cost can range between $60,000 and $120,000.

In one real-life example, a homeowner in rural Pennsylvania built a 750-square-foot modular cabin with mid-grade finishes and basic appliances. With site prep, utility hookups, and delivery included, the entire project cost just under $98,000. That’s incredibly reasonable compared to a traditional home of similar size, which might cost $130,000 or more.

These smaller modular homes are also ideal candidates for off-grid or energy-efficient upgrades like solar panels, composting toilets, and tankless water heaters, making them even more attractive for eco-conscious buyers or those looking to live a minimalist lifestyle without sacrificing comfort.

Mid-Size Family Modular Home

For growing families, a 1,500 to 2,000-square-foot modular home offers the perfect balance of space and affordability. These homes usually feature three bedrooms, two bathrooms, a full kitchen, and open-plan living/dining areas. Depending on your choice of layout, materials, and extras like a garage or porch, you’re looking at a cost range of $160,000 to $250,000.

Take, for instance, a case study from Texas where a family of four built a 1,800-square-foot modular home on their own land. They opted for upgraded appliances, a custom kitchen island, and energy-efficient HVAC. Their total cost? Around $210,000—nearly $100,000 less than a similarly sized site-built home in the same area.

The major advantage in this scenario was how quickly the family could move in—just three months from ground-breaking to occupancy. Plus, their utility bills are significantly lower thanks to the home’s tight construction and smart energy features.

Luxury Modular Home Example

Yes, luxury and modular can coexist. In fact, high-end modular homes are quickly becoming a trend among homeowners who want premium features without the lengthy construction timelines of traditional builds. These properties, which exceed 2,500 square feet and often include four or more bedrooms, custom architecture, and premium finishes, can cost anywhere from $300,000 to $600,000+.

One notable example comes from California, where a couple built a 3,200-square-foot modern modular home featuring floor-to-ceiling glass walls, a rooftop deck, solar panels, and a built-in home automation system. Including all the extras—foundation, site work, high-end appliances—the final cost reached $520,000.

While this might not seem like a huge discount from traditional luxury homes, the time savings and superior construction quality (thanks to the factory-controlled environment) made it a worthy investment. Plus, the resale value for luxury modular homes is trending upward, especially in urban and high-demand markets.

Common Mistakes to Avoid in Budgeting

Underestimating Site Costs

One of the biggest financial missteps modular home buyers make is underestimating the costs associated with site preparation. While the modular home itself might seem affordable, the process of getting your land ready can blow up your budget if you're not careful.

Clearing the lot, grading, installing drainage systems, digging trenches for utilities, and pouring the foundation—all of this can cost as much as $20,000 to $50,000 or more, depending on your location and lot condition. Rocky terrain, poor soil quality, or access issues can push that number even higher.

The solution? Do a thorough site analysis before you finalize your home design. Hire a land surveyor and work closely with a builder who can assess potential challenges early on. That way, you can plan around expensive surprises rather than react to them later.

Ignoring Hidden Charges

Modular homes are marketed as budget-friendly—and they are—but there are hidden costs that can creep up if you’re not paying attention. Common “gotchas” include:

- Utility connection fees (especially in rural areas)

- Permit and inspection fees

- Delivery charges and crane rental

- Interior customization costs

- Landscaping and driveway installation

Some buyers also forget to factor in the cost of temporary housing if they’re selling their current home before the modular one is ready. It’s these little expenses that add up quickly and can turn a great deal into a financial headache.

Be sure to get itemized quotes from your builder and cross-check those numbers with your cost estimator. Transparency is your best friend during the budgeting process.

The Future of Modular Home Design and Pricing

Trends in Smart Modular Living

Modular homes are no longer just about affordability—they're becoming tech-savvy sanctuaries. The latest trend is the integration of smart home technology directly into modular builds. Think voice-activated lighting, climate control systems, security cameras, and even built-in AI assistants. Many modular home companies now offer these features as standard or low-cost add-ons.

Another hot trend? Sustainable and green design. Builders are moving toward using recycled materials, solar energy systems, rainwater collection units, and energy-efficient appliances. Even passive solar design—where window placement and building orientation reduce energy use—is becoming common in modular layouts.

Tiny homes and ADUs (Accessory Dwelling Units) are also surging in popularity, especially in urban areas where space is limited but housing demand is high. Expect more multi-functional, compact modular units to pop up in cities across the country.

Price Predictions for the Coming Years

So what’s on the horizon for modular home pricing? While construction material costs may continue to fluctuate due to inflation and supply chain issues, modular homes are expected to maintain their cost advantage over traditional builds.

In fact, as demand grows and manufacturing scales up, prices may even stabilize or decrease in some regions. Automation and AI in modular factories are driving efficiency and reducing waste, which could eventually lead to lower costs for consumers.

Modular homes are well-positioned to meet the evolving needs of modern homebuyers—affordability, speed, sustainability, and tech-integration. If you're thinking long-term, investing in a modular home today could be one of the smartest moves you make for your financial future.

Conclusion

Modular homes have redefined what it means to build affordably, efficiently, and beautifully. With the help of a reliable modular home design cost estimator, you can plan your dream home with clarity and confidence. From understanding site costs and hidden fees to comparing designs and exploring financing options, estimating your modular home’s cost is the first—and most essential—step toward building smart.

Whether you're dreaming of a small cozy cabin, a spacious family home, or a luxurious custom estate, modular construction offers flexibility without breaking the bank. So plug your numbers into an estimator, weigh your options, and take the next step toward a future where quality meets affordability.

FAQs

1. What is the average cost per square foot for modular homes?

The average cost per square foot ranges between $50 and $150, depending on design choices, location, and customization.

2. Are modular homes cheaper than traditional homes?

Yes, modular homes are typically 10–30% less expensive than site-built homes due to efficient factory construction and lower labor costs.

3. How accurate are modular home cost estimators?

While not exact, they offer a highly accurate ballpark figure when detailed inputs are provided. Always consult a builder for a final quote.

4. Can I customize my modular home fully?

Absolutely. You can choose layouts, materials, finishes, and features. Just remember, the more customization, the higher the cost.

5. How long does it take to build a modular home?

On average, 3 to 4 months from start to finish, including design, construction, delivery, and on-site setup.

My name is Mahi Uddin, and I’m a blog writer with over two years of experience specializing in creating engaging, informative content using AI tools. I contribute to InExDecor.com, where I share creative ideas and practical tips for transforming interior and exterior spaces into beautiful, functional environments. With a passion for storytelling and a knack for blending creativity with technology, I strive to craft blogs that not only inform but also inspire readers. When I’m not writing, you can find me exploring design trends or enjoying a good book with a cup of coffee.